Before diving deeper into the theory of DP, it is wise to give one an answer – why do we actually need dynamic positioning? Another example is platform supply operations offshore.

Let’s assume that a vessel is required to approach an offshore installation keeping relatively low speed, establish a working position with a fixed heading, and then keep both over a prolonged time. How can this be achieved, if there is not such option as anchoring or tying up to that installation?

In the old days, mariners were keeping their position in manual mode. Although it did develop mighty skills of ship handling, it imposed a heavy load on the bridge team, and most importantly, made such a vessel liable to direct influence of a human error, not barriered by automatic preventive means and warnings about undesired situations being developed.

Due to this reason, most of the modern platform supply vessels are being built with dynamic positioning capability. Under strict supervision of a qualified operator, the overall performance and efficiency of such works are both way higher.

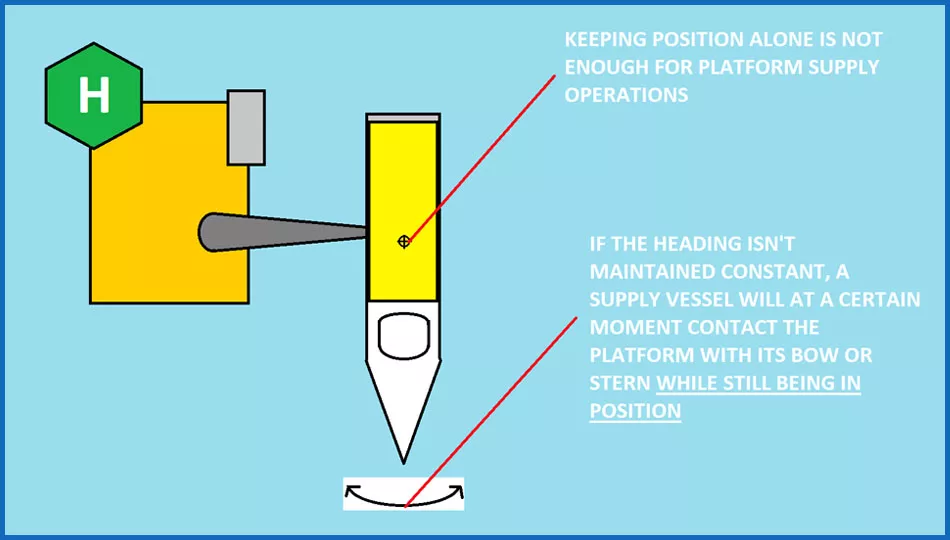

Let us clarify why keeping just a position, without a fixed heading, is not enough. This will also hint us why without a well-stabilized heading, a precise station-keeping is barely possible. Imagine a vessel that is only trying to be bound to keeping an exact position, but the heading isn’t fixed. The vessel’s DP system calculates and generates thrust relative to its default center of forces application, which is termed in distances fore/aft and port/starboard from the center of gravity (as close to that point as practicable).

Thus, if heading is not fixed, every other second a direction of the thrust vector in terms of ship-bound orientation may be different. Thus, precise station keeping is impossible. Moreover, the vessel sooner or later will collide a platform with its bow or stern extremity, while still being in station-keeping mode and “keeping its position”.

Over a time often referred to as “DP Setup”, the DP system will “collect the information” on the environmental forces acting on the vessel, and “take a weighted and stabilized decision” as to what is the total magnitude of the thrust to be generated in order to keep heading and position, and in which direction and rotary moment such thrust is to be applied.

Needless to say that a vigilant DP operator isn’t confined to only perform inputs and control the vessel’s DP system, but also is ready to take a manual control of the vessel, should the DP system fail to function as required. Offshore supply operations most commonly mean a prolonged station-keeping period, and performing such a work in manual mode is more than exhausting. While a practice of tie-up or combined anchor and tie-up operations are becoming obsolete, the absolute majority of the offshore energy businesses require dynamic positioning capability to be provided in order to be considered fit for work.

Our particular emphasis at LERUS is that, we do not only teach a dry theory but we share our vast practical experience in explanations and simulator exercises so that extended position-keeping periods are being held with the best efficiency of the vessel’s power plant, and with no compromise on safety. Come study with LERUS!